What are the five essentials of operational excellence? How do we make kaizen a daily work habit?

The Five Essentials of Operational Excellence

What are the five essentials of operational excellence? How do we make kaizen a daily work habit? What key work system changes do leaders need to make? To what degree do your existing work system designs discourage versus promote daily kaizen and operational excellence?

I have learned through the Baldrige National Quality Award process, and Phillip Crosby, that all work is a process. In turn, if we can make all of our work processes excellent, we can build excellent organizations as well.

Do you want to both satisfy staff expectations and minimize costs and waste? If so, keep in mind that an effective operational excellence strategy includes the five essential elements I share in this post. as a bonus, I include some common operational excellence and kaizen questions that people ask.

What is Operational Excellence?

I base my definition of operational excellence on the criteria of the Malcolm Baldrige National Quality Award, and how I have seen recipients of the award apply these criteria to make their organizations more sustainable. Operational excellence must be demonstrated by results, not just in words.

45% of the 1,000 points that make up the Baldrige award criteria focus on results. In order to earn the maximum of these 450 points, an organization must sustain improvement over time. Also, they must do this in all areas of importance, against ‘best in class’ organizations.

Great organizations demonstrate operational excellence by results that reflect three things. First, they sustain improvement over time. Second, improvement is evident in all areas of importance (both performance areas and segments within each area). Finally, this mix of performance results should be at a level that is at, or better than, ‘best in class’ organizations.

Common areas of importance for a cost center are safety, quality, people, and cost. Profit centers add the revenue generation performance area to this mix. Common segments within each performance area include employee groups, facilities, departments, and external customer types.

How does operational excellence compare to process excellence?

My operations background as a production supervisor and plant manager influences my answer to this question to some degree. To me, process excellence reflects a broader focus than operational excellence does.

For example, with a process excellence focus, leaders expect groups like the sales force, marketing department, and upper management teams to also consistently improve the processes they own, just like the people in operations do.

I see the phrase “operational excellence” as being potentially restrictive. Process excellence encompasses all work, whereas operational excellence may focus more on those processes that exist directly in the value stream.

All work is a process!

My preference is to pursue process excellence over operational excellence. The superior results that Baldrige recipient organizations are able to sustain convince me that we should view ALL WORK as a process.

Many lean initiatives are difficult to sustain simply because we fail to involve all work groups in the lean effort. In other words, the operations people make improvements, but the sales and marketing teams fail to improve in a similar manner.

In turn, companies find that they need to layoff people as a result of their lean operations improvements. They fail to use the time and money they save to support sales growth from current and new customers. Has a narrow operational excellence focus made it difficult to sustain your improvement initiatives?

NEXTGEN LEADER STANDARD WORK

Work system design most affects how people in formal leadership roles spend time. A foundation of effective NextGen Leader Standard Work job designs determines how leaders spend their time, each day, at work. In turn, operational excellence begins with great NextGen Leader Standard Work job designs.

Unfortunately, few organizations measure, trend, and improve how they manage meetings, communicate with their teams, or develop themselves or others. NextGen Leader Standard Work is a ‘must’ if you want to reduce waste, let alone sustain continuous improvement and operational excellence.

Plus, our work system designs determine WHO we engage with and HOW we engage with them. Consistent, meaningful collaboration is a must in the NextGen workplace. Continuous improvement is necessary for survival in a competitive, global, and ultra-dynamic business, if not life, climate.

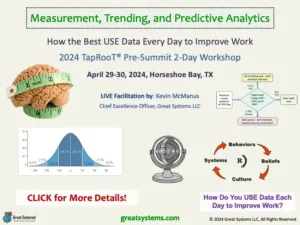

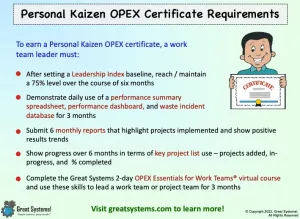

My Personal Kaizen Process Excellence certificate process is one way to help your leaders make the NextGen Leader Standard Work transition. This process has been proven to work in multiple organizations, both formally and informally.

My ‘personal kaizen’ certification process gives you a multi-faceted way to gauge daily continuous improvement work habit practice. Plus, the process lays an effective foundation for the organization’s pursuit of operational excellence.

TOTAL WORK TEAM ENGAGEMENT

How engaged are your work teams? Total work team engagement is essential if you want to make kaizen a daily work habit, let alone pursue operational excellence. To increase work team engagement, we must start with an effective work team infrastructure.

All too often, our current work system designs limit consistent collaboration, relationship growth, and process change. All leader time goes to manage daily value stream and support process performance. No leader time for continuous or reactive improvement exists.

As a result, we waste a lot of time and money each day. Daily problems and waste drive down team morale and motivation levels. Worse yet, we create a workplace where few people want to spend time. In turn, motivation and focus drift.

How Many Effective Work Leaders Make Up Your Leadership Team?

However, we can’t simply form teams and solve problems. First, we need effective project and focus team leaders.Then, we need an effective team infrastructure that helps minimize team waste and focus team continuous improvement efforts.

Most importantly, we need to include time for improvement in the job designs of both of team members and leaders. No time for daily kaizen is the primary performance restrictor in most organizations. Leaders need time to increase team engagement levels as well.

PROACTIVE PROCESS IMPROVEMENT

Third, we want every work team, through its leader, to consistently drive down errors and waste via daily proactive continuous process improvement. This area, like team engagement, gets little focus in too many cases.

The intent exists, but there simply is not enough time in the job. Too much daily Leader Standard WASTE exists. Plus, most people simply don’t have time in their jobs to contribute to effective continuous process improvement beyond idea submittal.

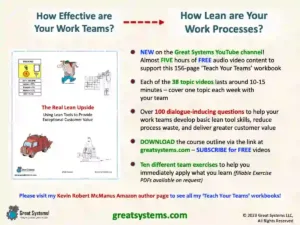

To minimize waste, all team members must develop and practice lean six sigma and other continuous improvement skills each day. For example, leaders can teach their teams how to practice 5S work habits on a daily basis.

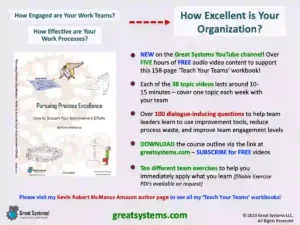

My Great Systems YouTube channel provides over 30 videos and five hours of FREE content on the basics of lean six sigma and other continuous improvement tools.

WORKPLACE SAFETY, HEALTH, AND RISK MINIMIZATION

Often, this is most obvious in the areas of workplace safety, security, and risk management. Without improvement time in their jobs to address these areas, leaders struggle to minimize error rates, injuries, and equipment failures.

Instead, they react all day to problems. To sustain true work team engagement over time, leaders must address these core engagement factors first.

Recurring Failure Reduction

Once we address our daily team safety and security needs, we can focus on recurring failure reduction. Effective equipment reliability and asset health management practices are critical tools for daily errors and failure minimization. I can show you how to engage leaders at all levels to track, and work to reduce, such work process challenges.

WORK SYSTEMS OPTIMIZATION

The ultimate goal of an OPEX effort is to integrate our great work systems into a cohesive, complimentary infrastructure. Such an infrastructure should support our mission, vision, values, and strategic objectives. Currently, little time exists to benchmark better options.

Incremental process improvement, and a few pockets of excellence, seem to be the best we can achieve. Instead, we need work systems that help make continuous process improvement a daily work habit!

To tie it all together, senior leaders must optimize work system design through work process integration, digital transformation, and best practice design application. You don’t have to take time to re-invent the wheel. Best practice tools, blueprints, workflows, and designs exist.

Where should you start your OPEX journey?

To improve, you just need to model, adapt, and utilize the resources I share on this site. Begin by exploring the links I share on this page. If you can’t find what you need, please connect and message me.

Don’t make your pursuit of daily kaizen and operational excellence such a challenge. Remember, work system design drives daily kaizen and work team performance.

Please take the time to explore how best practice work systems can help you make continuous improvement a daily work habit and accelerate your operational excellence pursuit. Keep improving … a little bit more each day!

How do lean methodologies contribute towards operational excellence?

Stated simply, the goal of any lean initiative should be to minimize waste and to maximize customer value. In an operationally excellent organization, leaders apply lean practices to all key processes, not just those of an operations nature. Additionally, they define value from the perspective of both the external and internal customer in a measurable manner.

Value is not just what management thinks the customer wants. Lean tools are just that – a set of tools that can be used on a regular basis to help you pursue operational and process excellence.

According to Womack and Jones, there are seven types of process waste – rework, overproduction, excess inventories, non-value added process steps, excess people movement, excess material transportation, waiting, and non-value added goods of services. Common examples of process waste in organizations include injuries, rework, downtime, and material waste.

Additional examples include absenteeism, equipment damage, product damage, customer complaints, and lost customers. A variety of lean tools are used to reduce and minimize these common causes of waste across the organization’s value stream (from supplier to end customer).

BUY my “Real Lean Upside – Lean Tool Basics” workbook NOW at Amazon.com

How does the use of six sigma, kaizen, and project teams affect operational excellence potential?

Six sigma, at its core, is simply a measure of process variation. In an operational or process excellence world, all work teams track and work to minimize process variation. They do this via the use of effective waste stream identification, root cause analysis, and project-driven work systems change.

The use of process improvement teams helps support the daily continuous improvement efforts of each work team leader. Both work team leaders and process improvement teams drive the operational excellence initiative.

Too many companies exclude their work team leaders and teams from the continuous improvement effort. They push towards operational or process excellence as a goal.

However, they rely primarily on their process improvement teams to drive their process improvement efforts. In doing so, they fail to attain high levels of employee engagement in the pursuit of process excellence.

How would you define ‘World Class’ in terms of operational excellence?

Organizations exemplify world class operational excellence through the selection of global ‘best in class’ benchmarks. For example, an organization might be able to demonstrate ‘best in class’ performance within its industry in the United States. However, their results may carry less value against a broader set of competitors.

Globally, an operationally excellent organization at the world class level can demonstrate superior performance against organizations that extend beyond its industry and country of operation. Most organizations are content to surpass the industry average within their country of operation. However, this is not world class excellence.

EXPLORE MORE: Operational Excellence Barriers

As an Examiner for the Malcolm Baldrige National Quality Award, what attributes do you look for to gauge operational excellence?

I essentially answer this question with my definition of operational excellence. I will add that there are three key things we examiners look for, especially when we visit a finalist for the award. First and foremost, we try to ask questions of a high percentage of the workforce to help validate the degree of high performance work practice deployment.

You can’t achieve a significant percentage of the award’s ‘approach / deployment points (55% of the total) without key approach deployment to a high percentage of the workforce. In other words, a high level of employee engagement is a prerequisite when you truly pursue operational and process excellence.

Secondly, we review lots of documentation and talk to more people. We want to validate the degree that what was said on paper actually exists in the organization. Eleven core values serve as the foundation for the award and its criteria.

These core values include fact-based management, visionary leadership, and valuing employees. Most organizations can talk a good game, but few can back it up in the workplace.

That’s where the third thing comes in. Even in those cases where an organization might have the right work systems in place, they can rarely demonstrate how they consistently improve these systems to produce better results, in all areas of importance.

EXPLORE MORE: How to Use the Baldrige Award Criteria to Measure Operational Excellence

What is the most “critical factor” that makes an improvement initiative successful?

This is a tough question, because I am torn between two possible answers. An improvement initiative will not succeed if leaders fail to allocate time towards the effort. Once leaders allocate that time, they must use it effectively.

That said, organizations often allocate this time on paper (in a strategic plan, job description, or expense budget for example). Unfortunately, they fail to require EACH leader to demonstrate how they personally use this time to improve the key processes they are responsible for.

If I could only change one thing, I would change what I expect from each of my leaders. Most people will find a way to reach a goal if leaders clearly state that goal, along with the goal achievement consequences.

LEARN MORE: How to Measure and Improve Your Leadership Work System

What is “Activity Based Costing”?

My experience convinces me that activity based costing (ABC) is a requisite for operational excellence. Most importantly, ABC helps you allocate overhead to each product more effectively, instead of using ratios based on a percent of direct labor dollars, pounds per labor hour, or line hours. With ABC, leaders identify the primary cost driver for each expense group (cost center). Then, they derive product specific percentages for each cost driver.

For example, we might use a percentage of floor space a product occupies to allocate rental expense to each product. Engineering or sales wages and benefits are allocated to each product or service based on the amount of time each engineer or sales person reports spending on a given product. You can base human resource cost allocations on the number of labor hours each product totals.

The key is that the cost driver type varies with each cost center. We don’t use a single set of multipliers to allocate all overhead costs. Using ABC helps more clearly define a product’s or service’s true profit margin. Without its use, one product or service may carry an excessive amount of another product’s overhead burden.

BUY my “Pursuing Process Excellence” workbook NOW at Amazon.com

How does the use of “Activity Based Costing” support “operational excellence”?

For example, I have seen one candy bar type essentially die on the vine because it carried an excessive amount of sanitation labor costs. Sanitation costs were allocated based on line hours of operation, instead of on the sanitation hours that were actually needed to clean the line.

Both products ran for the same amount of time each week. The other product was very messy, and it required twice as many people for clean up. In turn, the ‘easy to clean’ product’s profit margin was understated, and management was hesitant to grow that brand. Additionally, the profit margin for the messy product was overstated.

ABC also helps an organization focus more on transaction costs. Leaders don’t merely manage to the monthly budget numbers. In an operationally excellent organization, the goal should be to consistently drive down the cost per transaction (i.e. the cost per pound or the cost per customer) in EACH process area, not just overall.

ABC helps non-production groups in particular, because it helps clarify the primary reason they exist. For example, what is the human resource cost for each person you hire or per employee? How has, or might, this number change over time?

How can managers ensure supervisors properly carry out the daily tasks and duties necessary to maximize the effectiveness of the improvement process?

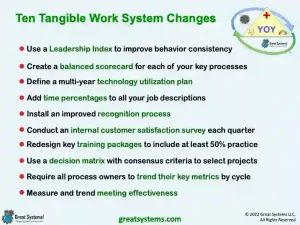

As with any type of supervision or process ownership, we should use a balanced set of metrics and reports to track leadership behavior and task effectiveness. For example, you can provide a ‘bottom up’ Leadership Index to each supervisor at least once a year as a behavior effectiveness metric.

Hold work team leaders responsible for the safety, cost, quality, and people metrics that his or her processes produce over time. Results should be evident in the form of trend lines and a balanced scorecard.

A key mistake most organizations make is to expect an external department, such as Safety, Quality, or Human Resources, to manage the process results in these areas across multiple process groups.

Plus, I expect each of my process owners to provide ‘evidence of excellence’ each month. Such evidence includes a key project list for their processes, a monthly summary of their key accomplishments and challenges, and a performance summary spreadsheet that shows DAILY process inputs and outputs.

Because I expect my supervisors to spend 30-60 minutes a day on these items and use a spreadsheet to compile and organize them, I can review their progress at any time by simply looking at the spreadsheet itself, the results trend lines posted in their process areas, and/or their hard copy monthly report (or intranet web page).

Keep improving!

Kevin McManus, Chief Excellence Officer, Great Systems

WATCH over 50 kaizen and workplace health improvement videos on my Great Systems YouTube channel.

CHECK OUT my ‘Teach Your Teams’ workbooks on Amazon.com

LIKE Great Systems on Facebook

© Copyright 2024, Great Systems LLC, All Rights Reserved