Continuous Improvement and Operational Excellence Coaching

Great Systems Continuous Improvement and Operational Excellence Coaching

How can Great Systems continuous improvement and operational excellence coaching help your work teams and leaders sustain workplace health?

Hi! - My name is Kevin McManus. As the Chief Excellence Officer of Great Systems, my goal is simple and twofold. First, I want to help you achieve better performance results, from both your work processes and work teams. Second, I want to help you eliminate the frustration that comes with improvement fad pursuits and wheel re-invention efforts.

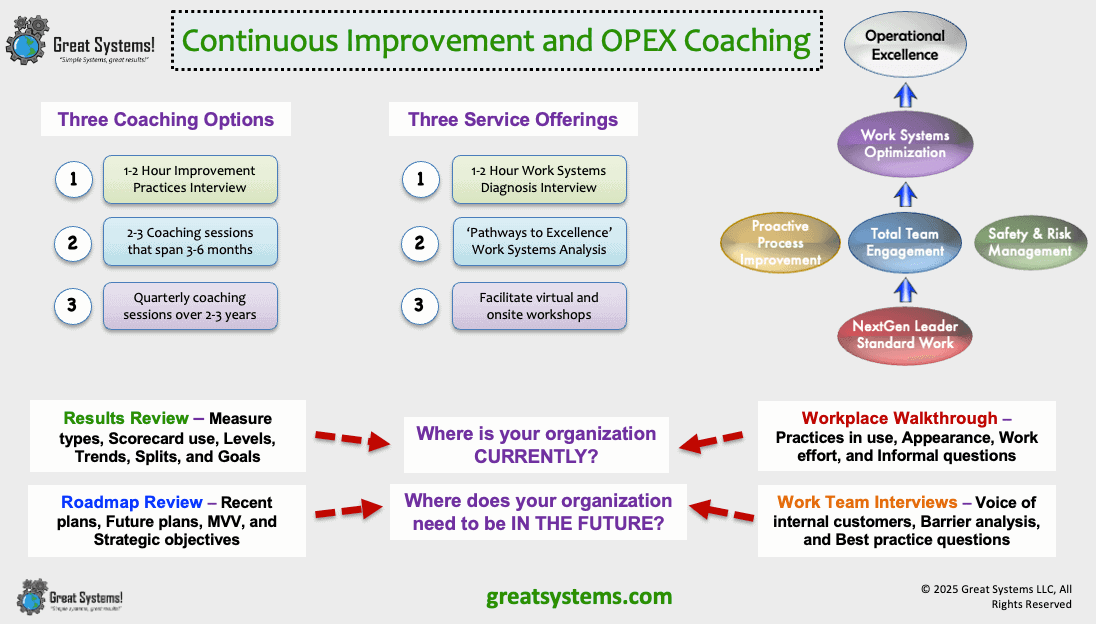

I provide three forms of confidential, high value continuous improvement and OPEX coaching:

Coaching Option #1: Most commonly, I simply spend 1-2 hours in a a virtual setting with the customer. In this setting, I listen to your key work systems challenges and your 'compelling why' for change. Then, I ask open-end questions to help diagnose and identify potential work system design flaws.

Coaching Option #2: A second coaching service option I offer involves the use of 2 or more sessions spread over time. A common example is the process leaders use to earn a Personal Kaizen OPEX Certificate and improve their daily on-the-job performance. These coaching engagements may of a training and/or consultive nature. Also, they may take place at the workplace.

Coaching Option #3: With this option, I interact with one or more of your work teams consistently over time. This coaching service is more common with those customers who lead large-scale change and OPEX efforts. As it is contractual by design, organizations can obtain high value in a relatively short amount of time.

Please contact me and REQUEST a FREE COACHING SESSION today!

Hi! - My name is Kevin McManus. As the Chief Excellence Officer of Great Systems, my goal is simple and twofold. First, I want to help you achieve better performance results, from both your work processes and work teams. Second, I want to help you eliminate the frustration that comes with improvement fad pursuits and wheel re-invention efforts.

I provide three forms of confidential, high value continuous improvement and OPEX coaching:

Coaching Option #1: Most commonly, I simply spend 1-2 hours in a a virtual setting with the customer. In this setting, I listen to your key work systems challenges and your 'compelling why' for change. Then, I ask open-end questions to help diagnose and identify potential work system design flaws.

Coaching Option #2: A second coaching service option I offer involves the use of 2 or more sessions spread over time. A common example is the process leaders use to earn a Personal Kaizen OPEX Certificate and improve their daily on-the-job performance. These coaching engagements may of a training and/or consultive nature. Also, they may take place at the workplace.

Coaching Option #3: With this option, I interact with one or more of your work teams consistently over time. This coaching service is more common with those customers who lead large-scale change and OPEX efforts. As it is contractual by design, organizations can obtain high value in a relatively short amount of time.

Please contact me and REQUEST a FREE COACHING SESSION today!

How Does Work Systems Redesign Help Improve Workplace Health?

Work systems design determines how people spend time at work. If you want to sustain high levels of 'best in class' performance, work systems redesign is mandatory in most cases. For example, most job roles do not include meaningful time for project work.

Few leadership development processes teach leaders how to practice empathy and encourage diverse thinking. We invest time to meet as groups, but we often waste a high percentage of that precious, limited resource.

Common work systems we can improve via virtual coaching include those you use for leadership development and strategic planning. Plus, I can share best practices to help you increase internal and external customer engagement levels. Finally, a variety of performance measurement and process improvement work system upgrades are available.

Work system designs give you the results that their designs guide them to produce. Work system design guides how people spend work time each day.

Let me show you how to install best practice work system upgrades that help your work teams and leaders use work time more effectively.

Few leadership development processes teach leaders how to practice empathy and encourage diverse thinking. We invest time to meet as groups, but we often waste a high percentage of that precious, limited resource.

Common work systems we can improve via virtual coaching include those you use for leadership development and strategic planning. Plus, I can share best practices to help you increase internal and external customer engagement levels. Finally, a variety of performance measurement and process improvement work system upgrades are available.

Work system designs give you the results that their designs guide them to produce. Work system design guides how people spend work time each day.

Let me show you how to install best practice work system upgrades that help your work teams and leaders use work time more effectively.

I consider myself fortunate to have always worked in organizations that at least tried to make process improvement and employee involvement part of their work cultures. I have learned from these experiences, largely because I worked in places where at least one person, if not more, both supported me and allowed me to experiment.

WATCH over 50 kaizen and workplace health improvement videos on my Great Systems YouTube channel.

WATCH over 50 kaizen and workplace health improvement videos on my Great Systems YouTube channel.

Work System Design and Improvement Challenges

From the Internet, people can easily learn more than they ever need to know about operational excellence and process improvement strategies. However, three implementation challenges exist. First, you must design work systems that give people time to use improvement tools. Second, your work system designs need to support your mission, vision, values, and strategic intent.

Last, leaders must execute both actions in a manner that achieves high levels of meaningful workforce engagement. Over my 40-plus year career, I have acquired a vast collection of effective work system designs. Plus, years of personal experimentation and 'best in class' benchmarking has helped me enhance many of these designs.

My goal is to provide each of my customers with the utmost value, and I am not just saying that. By the way, my definition of value is "what one gets for what it costs them", both in terms of time and money. I am 100% confident that if you give me the chance to work with you and your team, I can show you how to get great results in a short amount of time, without investing minimal extra time.

In fact, I am also confident that you will save money. I hope that I can have the chance to talk with you about how to make your work systems redesign efforts.

Last, leaders must execute both actions in a manner that achieves high levels of meaningful workforce engagement. Over my 40-plus year career, I have acquired a vast collection of effective work system designs. Plus, years of personal experimentation and 'best in class' benchmarking has helped me enhance many of these designs.

My goal is to provide each of my customers with the utmost value, and I am not just saying that. By the way, my definition of value is "what one gets for what it costs them", both in terms of time and money. I am 100% confident that if you give me the chance to work with you and your team, I can show you how to get great results in a short amount of time, without investing minimal extra time.

In fact, I am also confident that you will save money. I hope that I can have the chance to talk with you about how to make your work systems redesign efforts.

What is Work Systems Redesign?

My operational definition of a system is based on the use of the term "systematic" in the Malcolm Baldrige National Quality Award criteria. That definition refers to "approaches that are well ordered, repeatable, and use data and information so that improvement and learning are possible." I would say that in most organizations, their work systems are repeatable, even though the results they provide or the waste they contain are not actually measured.

Unfortunately, the work processes people repeat each day as a part of a given work system (1) fail to produce the types of results stakeholders desire and (2) are not executed in a similar manner across all people and work groups.

I help leaders at all levels improve the work systems they already have in place. At other times, I help them install new system designs. My work system redesign experience and capability covers all key work system types.

For starters, I can work with your leadership team and other key personnel to evaluate the effectiveness of your current work systems. More importantly, I can recommend possible options to make your work systems more effective. I can also focus specifically on improving a given process or job, using my industrial engineering and process improvement skills.

Unfortunately, the work processes people repeat each day as a part of a given work system (1) fail to produce the types of results stakeholders desire and (2) are not executed in a similar manner across all people and work groups.

I help leaders at all levels improve the work systems they already have in place. At other times, I help them install new system designs. My work system redesign experience and capability covers all key work system types.

For starters, I can work with your leadership team and other key personnel to evaluate the effectiveness of your current work systems. More importantly, I can recommend possible options to make your work systems more effective. I can also focus specifically on improving a given process or job, using my industrial engineering and process improvement skills.

Workforce Engagement, Continuous Improvement, and Operational Excellence

Most organizational continuous improvement and operational excellence efforts are significantly constrained. It is common to see such approaches (typically a few six sigma, lean, or kaizen teams) only engage 10-15% of the organization's workforce. However, in high performance organizations, it is common to involve 65% or more of the people on some form of project team.

Additionally, these leaders engage 100% of their people at least monthly in formal process and performance review, and idea sharing, sessions. The best organizations engage 100% of their people on a daily basis in continuous improvement. They practice "operational excellence from the inside out."

DOWNLOAD my 'How to be Proactive with Daily Work Process Improvement' eBook

I have spent years working in, and with, these types of high performing organizations. I can help you install systems that will engage every employee in the daily pursuit of process excellence. My learnings can help you improve the effectiveness and level of involvement in formal problem solving efforts.

Also, I can help you manage the evaluation and implementation of the great ideas that your people have, but you may not be aware of. Most importantly, I want to help you put systems in place that drive improvement and high levels of staff engagement and ownership. Why merely hold training sessions or make lists of ideas people will never work on or put in place?

Additionally, these leaders engage 100% of their people at least monthly in formal process and performance review, and idea sharing, sessions. The best organizations engage 100% of their people on a daily basis in continuous improvement. They practice "operational excellence from the inside out."

DOWNLOAD my 'How to be Proactive with Daily Work Process Improvement' eBook

I have spent years working in, and with, these types of high performing organizations. I can help you install systems that will engage every employee in the daily pursuit of process excellence. My learnings can help you improve the effectiveness and level of involvement in formal problem solving efforts.

Also, I can help you manage the evaluation and implementation of the great ideas that your people have, but you may not be aware of. Most importantly, I want to help you put systems in place that drive improvement and high levels of staff engagement and ownership. Why merely hold training sessions or make lists of ideas people will never work on or put in place?

'Teach Your Teams' Kaizen Workbooks and Learning Process

If you invest eight hours of your time in a training session, then you should get eight hours of value. The design of my virtual workshops allows time for a lot of skill practice and interaction. This is how adults learn best. Skill understanding, retention, and application are the goals. Lecture-based training will not help you achieve these goals, but my interactive workshops will!

The modular design of my 'Teach Your Teams' continuous improvement workshops helps you customize the workshop content to focus on those skill areas you feel need the most attention. For example, let's say that you want to focus more on quick changeover tools and less on visual management in the "Lean Tools Basics" workshop. Individual lessons and videos are easily interchangeable.

Currently, you can find full audio and video support for three of my most popular workbooks on my Great Systems YouTube channel. One playlist for each workbook exists for on-demand learning. Plus, 'fillable form' exercise PDFs are available upon request to support each lesson.

Plus, you can customize my workshop exercises to help link the concepts we share and practice to your daily workplace. If you would like more information about the improvement tools and systems I have to offer, please use this form to connect with me or send me an e-mail at kevin@greatsystems.com.

The modular design of my 'Teach Your Teams' continuous improvement workshops helps you customize the workshop content to focus on those skill areas you feel need the most attention. For example, let's say that you want to focus more on quick changeover tools and less on visual management in the "Lean Tools Basics" workshop. Individual lessons and videos are easily interchangeable.

Currently, you can find full audio and video support for three of my most popular workbooks on my Great Systems YouTube channel. One playlist for each workbook exists for on-demand learning. Plus, 'fillable form' exercise PDFs are available upon request to support each lesson.

Plus, you can customize my workshop exercises to help link the concepts we share and practice to your daily workplace. If you would like more information about the improvement tools and systems I have to offer, please use this form to connect with me or send me an e-mail at kevin@greatsystems.com.

TapRooT® Root Cause Analysis Training

I have taught over 430 courses and helped more than 500 organizations as a certified international trainer for the TapRooT® root cause analysis process. I believe that this root cause analysis approach far exceeds the 'opinion-based' approaches that others use, such as fishbone diagrams, 5 Whys, and fault tree analysis.

Additionally, the TapRooT® root cause tree represents a collection of 103 best practices to improve human performance. In turn, you can use it to error proof your work systems. Do you want to reduce significant amounts of waste, improve customer satisfaction levels, and grow your business? If so, you need work systems that promote effective, daily human performance and minimize the potential for equipment breakdowns.

To learn more about this service that I provide, here are two options to consider. First, I would be happy to facilitate a TapRooT® 3-day virtual root cause analysis workshop for your team. To learn more, please check out the linked page or visit the TapRooT website.

Also, please check out my 'Evaluating Root Cause Analysis Processes' page, which can be found on this website .

Additionally, the TapRooT® root cause tree represents a collection of 103 best practices to improve human performance. In turn, you can use it to error proof your work systems. Do you want to reduce significant amounts of waste, improve customer satisfaction levels, and grow your business? If so, you need work systems that promote effective, daily human performance and minimize the potential for equipment breakdowns.

To learn more about this service that I provide, here are two options to consider. First, I would be happy to facilitate a TapRooT® 3-day virtual root cause analysis workshop for your team. To learn more, please check out the linked page or visit the TapRooT website.

Also, please check out my 'Evaluating Root Cause Analysis Processes' page, which can be found on this website .

'Big Picture' Problem Solving Facilitation and Safety Work System Redesign

Some of my TapRooT® customers enlist my services to help them analyze persistent problems. My use of onsite investigation interviews and facilitation, plus systems analysis and online consultation, helps you find the systemic causes of these problems.

More importantly, I can help you identify high-impact corrective actions, (systems changes) you can put in place. This helps minimize the likelihood that these problems return in the future. Also, I can help you measure and improve your investigation process so it routinely produces better results in less time.

If you would like more information about the improvement tools and systems I have to offer, please use this form to connect with me or send me an e-mail at kevin@greatsystems.com.

More importantly, I can help you identify high-impact corrective actions, (systems changes) you can put in place. This helps minimize the likelihood that these problems return in the future. Also, I can help you measure and improve your investigation process so it routinely produces better results in less time.

If you would like more information about the improvement tools and systems I have to offer, please use this form to connect with me or send me an e-mail at kevin@greatsystems.com.

Baldrige Quality Award Based Services

I am proud of my twenty years of service as a National Examiner for the Malcolm Baldrige National Quality Award. My participation in the Baldrige process as an Examiner enhanced my work career than any of my other personal development efforts. This includes my MBA degree work.

I have had the chance to create over 40 scorebooks and go on fourteen national site visits. I have been able to serve as both a Team Leader and a back-up team leader on consensus teams and site visit teams. Most importantly, my service as an Examiner helps me see what true, sustained operational excellence looks like in a variety of work settings.

This includes small business and health care. Plus, I continue to explore how Baldrige recipients use systems redesign to build better organizations and communities. As your virtual work systems redesign coach, I want to show you how to use 'best practice' work system designs to help attain similar results in a value added, cost effective manner.

Here are some VIRTUAL services that I offer to help you and your organization specific to a Baldrige-based pursuit of process excellence:

* One and Two-Day Self Assessment Workshops

* Application Writing and Assembly

* Half Day Systems Redesign Workshops

* Site Visit Readiness Reviews and Simulations

I have had the chance to create over 40 scorebooks and go on fourteen national site visits. I have been able to serve as both a Team Leader and a back-up team leader on consensus teams and site visit teams. Most importantly, my service as an Examiner helps me see what true, sustained operational excellence looks like in a variety of work settings.

This includes small business and health care. Plus, I continue to explore how Baldrige recipients use systems redesign to build better organizations and communities. As your virtual work systems redesign coach, I want to show you how to use 'best practice' work system designs to help attain similar results in a value added, cost effective manner.

Here are some VIRTUAL services that I offer to help you and your organization specific to a Baldrige-based pursuit of process excellence:

* One and Two-Day Self Assessment Workshops

* Application Writing and Assembly

* Half Day Systems Redesign Workshops

* Site Visit Readiness Reviews and Simulations

Continuous Improvement and Operational Excellence Coaching for Healthcare

The four approaches I list above can also help improve health care systems from a Baldrige perspective. Also, my Industrial Engineering background allows me to help you make health care process-specific improvements.

For example, I have helped an intensive care pharmacy improve its work flow. Key results included a reduction in the average cost to fill an order AND a reduction in the potential for prescription errors.

For example, I have helped an intensive care pharmacy improve its work flow. Key results included a reduction in the average cost to fill an order AND a reduction in the potential for prescription errors.

Continuous Improvement and Operational Excellence Keynote Speaking

I regularly speak on high performance workplace and motivation topics at local, regional, and national events. Plus, I make organization-specific speeches. Currently, my most popular speeches are "Pursuing Operational Excellence - How to Sustain Your Improvement Efforts", "How to Overcome the Ten Cultural Challenges to High Performance", and "NextGen Leadership - the Key to Sustained Operational Excellence."