Learn about how Kevin McManus and Great Systems can help your leaders make kaizen a daily work habit and operational excellence a realistic goal!

About Kevin McManus and Great Systems!

Hi! I’m Kevin McManus, Chief Excellence Officer for Great Systems. Please let me take a few minutes of your time to tell you more about Great Systems. My focus at Great Systems is simple. I provide content and coaching that helps leaders make kaizen a workplace lifestyle and enhance workplace health.

A lack of time for improvement is a key factor that restricts any pursuit of kaizen and operational excellence. I want to help you find work time waste and convert it into proactive improvement time. Year over year, I continue to improve my work measurement, analysis, and innovation skills. Daily research helps me stay in touch with the new expectations of our post-pandemic, NextGen work world. We are not in Kansas any more, Toto!

Leader Standard Work is essential if one wants to improve more effective and engaged teams, design excellent work processes, and sustain great results. Together, we can work to develop and deploy proven Leader Standard Work best practices for all formal leaders.

Similarly, I share tools, blueprints, and workflows on this site to help you reduce waste and errors. More importantly, these tools help you create time for daily kaizen and project-based improvement.

Two Key Goals – Reduce Waste and Increase Customer Value

The primary focus of my work career has been consistent for decades. I want to make work a better place each day for all staff. Experience taught me that meaningful change of both a human and process nature is necessary to achieve this goal. Most leaders agree, but they fail to effectively use their limited improvement time.

Worse yet, too many leaders maintain legacy work practices consistently fail to support the engagement expectations of today’s internal and external customers.

How much time and money do you formally invest in improvement each day? For example, do you spend significant resources on incident investigations, process audits, and corrective action installation? Do you use lean six sigma project teams or kaizen teams to drive improvement over time?

How effective are your employee engagement and recognition efforts? What waste levels exist in your problem solving, root cause analysis, and asset reliability efforts? How often do these improvement processes give you the results you desire?

I can quickly help you get much more value from the daily kaizen and workplace health improvement resources you invest!

How to Improve Your Key Work Systems

All organizations have key work systems. However, they rarely perform at their optimum level. Consistent waste in the form of repeat errors and failures exists in our value streams and their support processes. Leaders struggle to invest enough resources in formal improvement, and the time and money they do invest produces marginal returns.

The amount of waste that is essentially built into these systems probably costs you a lot of non-value added time and money each day! Since 1980, I continue to search for the best work system designs. I know that I have found some great ones. The sustained results speak volumes.

I discovered many of these best practices during my twenty years of service as a Malcolm Baldrige National Performance Excellence Award Examiner. During this time, I was able to visit 14 different high performing organizations as a leader or member of a site visit team.

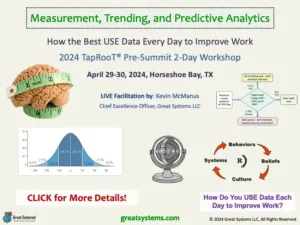

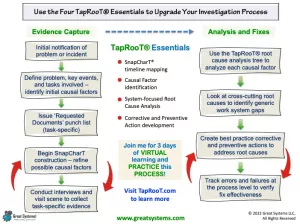

Plus, I found additional best practices while providing over 10,000 hours of TapRooT® root cause analysis training for twenty years.

What have I spent my career doing?

Given that I started all of this engineering and kaizen work stuff back in 1981, there have been three phases to my work career. Actually, my training and leadership development path began when I was 13. It is then that I began teaching others, working full-time to some degree, and learning myself. This seven years of growth included four summers in different roles at Philmont National Scout Ranch.

Phase #1 – 1981 to 2004

For the first 25 years of my work life, I helped manufacturing, process, and service organizations improve their work processes and systems. Past work team roles include Industrial Engineer, Production Manager, Plant Manager, Training and Development Manager, and Director of Quality.

Also during this time, I served as a regional Director, a multi-year national Board member and President for the Association for Quality and Participation. It was during this time that I was able to learn from people such as Peter Block, John Guaspari, John Schuster, and MaryAnn Brennan. Most importantly, I spent five of these years leading the effort to redesign AQP’s Team Excellence Award. Today, this award and its criteria are still in use by the American Society for Quality.

I left my last ‘real life work’ role as a plant manager in 2004, following company acquisition by a group with different work culture intentions. It’s sad, because that was the best team I had ever been a part of. This is when I began 15 years of weekly travel to teach TapRooT® root cause analysis process courses. Plus, I continued to serve as a national Baldrige Examiner on an almost annual basis.

Phase #2 – 2004 to 2020

Between October 2004 and March 2020, I taught over 430 TapRooT® root cause analysis courses. My travels took me to multiple continents and to businesses of a variety of types. My specialities include energy sector environmental analysis, repeat failure elimination, and proactive process improvement via mistake proof process designs.

I have more than 20 years of service as an Examiner (1998), Senior Examiner (1999, 2000, 2001, 2002, 2003), and Alumni Examiner (2005, 2007, 2008, 2009, 2010, 2011, 2012, 2013, 2014, 2015, 2016, 2017, 2018, 2019, 2020) for the Malcolm Baldrige National Performance Excellence Award. Plus, I served my last three years on the National Baldrige Judges Panel. My annual Examiner experience allowed me to be a part of 14 national site visits, where I could experience ‘real life excellence’ in action.

Phase #3 – 2020 to ????

The pandemic and its related events in 2020 and 2021 drove into a virtual work world. I taught almost 50 virtual root cause analysis courses, plus work of my own. A virtual set allows me to teach anywhere in the world, but I miss the human contact and interaction. Currently, I travel for work as long as the necessary arrangements can be made. Virtual course facilitation and coaching are available any time – just ask!

Also as a volunteer, I served as Vice President of Continuing Education on the IIE Board of Trustees. I am most proud of the fact that I have written the monthly ‘Performance Improvement’ column for Industrial and Systems Engineer magazine for over 20 years. Plus, I am a ATM-Silver certified Toastmaster. Most importantly, I take time to “sharpen my saw” every day!

What are my product and service offerings?

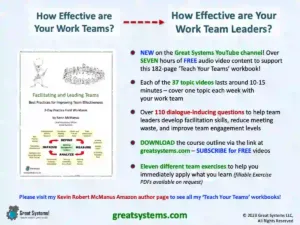

I work with organizations in three possible ways. Primarily, I provide virtual training and coaching to help you assess and improve work system and work team effectiveness. In each case, I use a team-based, highly interactive design to encourage involvement and the opportunity for skill practice. I design my books and workbooks to include (1) only the key information you need for success and (2) effective application exercises. My intent is to give you, the customer, the greatest value I can.

What are my key “high performance” beliefs?

The works of Deming, Covey, Robbins, and Senge form a foundation for what it takes to be a high performer from a beliefs perspective. Have you read the books that these four men have written? If so, you get a pretty good overview of what I believe “works at work” as well. Most important are my beliefs in (1) the untapped potential of all human beings, (2) the use of measurement and dialogue to understand systems, and (3) the need for simple systems.

Why should you do business with Kevin McManus and Great Systems?

- I have helped over 250 PROJECT TEAMS implement one or more process improvements

- I have more than 10 years of practice using process improvement tools AS A FRONT LINE LEADER (Plant Manager and Production Manager)

- Kevin has taught hundreds of courses and helped thousands of organizations find the true systemic root causes for thousands of incidents as a certified VIRTUAL TapRooT® root cause analysis trainer

- He has more than 20 YEARS of service as a National Malcolm Baldrige Performance Excellence Award Examiner, with three years as a Judge

- Kevin has 15 years of leadership with, and was a principal designer of, the AQP / ASQ International Team Excellence Award criteria

- Kevin has over 30 years of process improvement tool application and practice in a variety of organizations. He has never worked for a company that did not have a formal approach to process improvement in place!

How do I measure operational excellence (OPEX)?

For almost forty years, the Malcolm Baldrige National Performance Excellence Award criteria continue to evolve and improve. Today, I feel the Baldrige process represents the best model to assess performance excellence. In other words, if your organization can score well against the Baldrige criteria, then you will be a high performer.

I have learned a lot about the criteria as an Examiner, Senior Examiner, Alumni Examiner, and Judge. Plus, I have found ways for small and medium-sized groups to use the criteria and improve their work systems. In turn, their performance improves over time. Simple systems, when leaders design and implement them correctly, can yield great results.

Most importantly, I believe that an organization’s people – its associates and customers – serve as the best gauges of high performance. Fortunately, the design of the Baldrige criteria takes this critical human dimension of high performance into consideration. For example, two of the six Process categories focus on customer engagement and workforce engagement. Plus, two additional Results categories exist to drive the evaluation of results for each of these areas.

Giving Back

Giving back is fundamental to building great communities. Plus, I believe that service is the price we pay to live on the face of this earth. I was raised to support volunteerism, and I have done so consistently through my life. The more you give, the more you get back.

Great Systems recognizes the excellent efforts the following groups make towards improving our quality of life.

Malcolm Baldrige Performance Excellence Program

Additional Work Systems Improvement Links

Here are some additional links to resources that can help you further improve the effectiveness of your personal, team, and organizational work systems.

The Institute of Industrial and Systems Engineers

Performance Excellence Northwest Quality Award

Keep improving!

Kevin McManus, Chief Excellence Officer, Great Systems

WATCH over 50 kaizen and workplace health improvement videos on my Great Systems YouTube channel.

CHECK OUT my ‘Teach Your Teams’ workbooks on Amazon.com

LIKE Great Systems on Facebook

© Copyright 2024, Great Systems LLC, All Rights Reserved