Does your work team structure drive kaizen and operational excellence?

Does Your Work Team Structure Drive Kaizen and Operational Excellence?

Work system design determines how we spend time each day at work. The designs of our work team structures should drive daily kaizen, process improvement, and operational excellence, but do they?

First, most work teams spend the majority of their work time either in, or in support of, the different value streams. If time allows, they may practice proactive process improvement and spend time to develop cohesiveness.

Second, effective improvement work teams exist to support strategy and continuous improvement. Examples include ad hoc groups like safety committees, recognition teams, and leadership teams. Engineering and R&D teams spend 100% of their work time in improvement teams.

However, we can only support so many improvement teams. Value stream flow and support come first. All too often, value stream time requirements limit how much time we have left for improvement process execution.

What is a work team?

To begin with, what is a work team? You probably have at least one work team in place (unless you are a one-person organization).

In most cases, organizations have at least two of the three main types of work groups in place. Value stream work teams support external customers with their daily work. Value stream support work teams, such as Human Resources, IT, and Accounting, support one or more value streams.

Improvement work teams make up the third process work team type. Multiple types of improvement teams exist, with some being temporary. Examples include leadership teams, safety committees, and research and development, and engineering teams. At least, that is how it should work.

In most workplaces, such work teams exist. However, some of them may not be very effective. For example, people may work in a team, but they may not have much cohesiveness. In turn, you choose not to call them teams.

Nonetheless, these people depend on each other to get the work done each day. That is how I decide when I should assign the ‘team’ label to a group of people.

Do they depend on each other to get the job done each day? Does your work team structure drive daily kaizen and operational excellence?

How many work teams do you have?

The number of work teams you have, let alone create, matters. For example, you only have so many people with leadership skills.

How you use your work team time matters. Primarily, the value streams must take care of their customers. Additionally, you need to know your ‘total work teams’ number in order to define team support hours, expenses, and capital.

These days, most medium and large-sized organizations have too many improvement teams. Many meet regularly, but they are informal.

Often, improvement work team missions fail to align well with strategy. Plus, they may still fail to engage key internal and external stakeholders. A large percentage of the team time we do invest goes to non-value added topics, tangents, and discussions.

DISCOVER MORE: Work Team Characteristics – What is a Work Team?

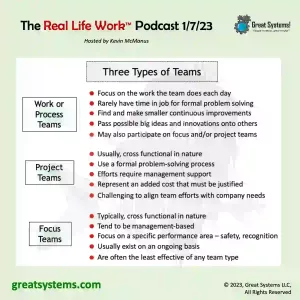

Aren’t there more than three types of work teams?

In my opinion, no. Of course, it depends on how you answer the ‘What is a team?’ question. I base my team and job design definitions on (1) how work time is spent daily and (2) the need for people to work together.

Experience teaches me that any organization needs three types of work groups to reach optimum effectiveness. To effectively sustain daily kaizen and pursue operational excellence, you need effective value stream, value stream support, and improvement work teams.

VALUE STREAM and VALUE STREAM SUPPORT WORK TEAMS

These work teams consist of people who work together in the value stream or in support of it. The degree of work team self-direction, or autonomy, varies. People who work in these two types of work teams spend most of their work time with the team.

FULL TIME IMPROVEMENT WORK TEAM

Full time improvement work teams include Engineering, Research and Development, and groups. These people spend 100% of their time type in the improvement team realm. Typically, their work is not seen as a process. In turn, work team effectiveness is not measured outside of department performance as a whole.

PROJECT IMPROVEMENT WORK TEAM

Quality circles, kaizen teams, tiger teams, six sigma teams, and problem solving groups are all examples of project work teams. These groups take time away from their ‘regular jobs’ to develop and implement improvement projects.

For these groups, working in a team is an ‘away from the normal workplace’ activity. This team type is rarely found in legacy workplaces. In turn, the status quo rules.

FOCUSED IMPROVEMENT WORK TEAM

This type of improvement work team is analogous to a safety committee, steering committee, recognition board, or management group. Like project teams, they tend to be cross-functional.

Also, ‘focused improvement’ work teams endure over time to support the primary goals of the organization. Unfortunately, too many companies fail to measure such work team costs or effectiveness, even though significant monies are spent on this team type.

What team types are in a work team infrastructure?

If you want your work team infrastructure to drive kaizen and operational excellence, you need three types of teams in place. All staff are members of at least one process work team. Process work teams exist in value streams or support value stream(s). The bulk of daily work time is spent here.

Also, people may serve roles on improvement teams. Typically, multiple types of improvement teams exist in a workplace. Examples include standing (focus) teams or temporary (project) teams.

The team structure defines how many teams of each type are needed to support strategy. In general, value stream and value stream support staff spend 90% of their time in their process work team. Engineers may spend 100% of their work time on one or more improvement teams.

How does team structure drive kaizen and operational excellence?

Organizations need effective value stream and stream support work teams to drive continuous improvement in an organization. Since they do not have much time away from the job to meet, these work teams do not have time to develop projects.

Their role is to identify and prioritize projects that need to be implemented. The lack of project time in their jobs limits their ability to work on projects themselves.

That is why we need project improvement work teams. People need time away from their primary job to work on projects. A person may be on both a value stream work group and a project team, but that does not have to be the case.

Finally, we need ‘focused improvement’ work teams to maintain a constant focus on those strategic areas key to the organization. Example focus areas include safety, cost reduction, waste reduction, recognition, and management.

If there are only three team types, what’s with all of the different names?

Cynics say that consulting firms create a lot of the different Improvement work team names to simply to make more money. For example, if quality circles don’t work, why don’t we call them problem solving teams?

Some group names help indicate differences in design or focus within a value stream or improvement area. For example, the structure of kaizen teams allows for faster project development (usually days) than the more traditional quality circle could produce (usually months). Shipping work teams fill that function within one or more value streams.

The degree of work team self-direction leads to additional potential work team names. Multiple strategic focus areas can result in a variety of improvement work team names.

How should we design jobs and budget resources to support improvement team involvement? How many different types of work teams do you need?

Budget for Formal Team Kaizen and Operational Excellence Investments

How much cost do you formally build into your product and service cost structures to cover team support? Each team type spends its work time in different ways each day to support site’s kaizen goals.

Here are some initial starting points that I have seen work well over time.

For value stream and support process work teams, an effective 5-10 minute daily huddle can have significant impact. The key is to emphasize key needs for the day, reinforce the team mission, recognize accomplishments, and update performance status. Always start here as you set aside time for formal improvement efforts.

Your site’s strategic objectives should drive the number of focus teams you need. Some objectives are addressed by existing project teams or other improvement groups.

From a time investment perspective, a percentage of hourly staff typically participate on safety and recognition committees. Be careful not to form too many ‘extra’ teams here.

As organizations grow in size, their project / improvement team counts grow as well. Smaller organizations may only have one or two project teams, if that.

This is the last area to consider when you build your annual kaizen budget. As you develop a project, the use of primarily informal communication can still lead to successful project completion.

How do I measure work team effectiveness?

Because they focus on process execution, each process work team has its own set of effectiveness factors. In my “Facilitating and Leading Teams” team effectiveness workbook, I include tools you can use to define and assess effectiveness for each team type. In general, we look at (1) results across multiple performance areas and (2) cohesiveness to measure group effectiveness.

Cohesiveness is necessary to help drive high levels of output. Keep in mind that most work groups don’t fail because of low cohesiveness. Instead, teams often fail due to a lack of proper support in the areas of information, recognition, resources, and alignment.

Example process output measures usually fall into the quality, safety, cost, and growth performance areas. Cohesiveness measures include absenteeism and tardiness rates, survey score results, and retention rates.

Most process work teams use some set of scorecard measures. Primarily, project work team measures look at performance to milestones and budget. Sadly, leaders often fail to track cohesiveness for project work teams.

Similarly, leaders often fail to measure focus work team performance. Do you measure safety committee or leadership team effectiveness?

Often, measures of focus team effectiveness come from annual survey statement responses. Improvement and project implementation rates versus team cost provide additional focus team effectiveness measures.

Keep improving!

Kevin McManus, Chief Excellence Officer, Great Systems

WATCH over 50 kaizen and workplace health improvement videos on my Great Systems YouTube channel.

CHECK OUT my ‘Teach Your Teams’ workbooks on Amazon.com

LIKE Great Systems on Facebook

© Copyright 2024, Great Systems LLC, All Rights Reserved