Root Cause Analysis Frequently Asked Questions Podcast

Welcome to this week’s edition of the Real Life Work podcast, brought to you by Great Systems. Today’s episode focuses on root cause analysis ‘frequently asked questions.’

I consistently encounter these questions as a contract virtual instructor for the Taproot® root cause analysis process. Please email or message me with your questions and podcast ideas.

More importantly, PLEASE SCROLL DOWN and enjoy the podcast.

How effective is your root cause analysis process?

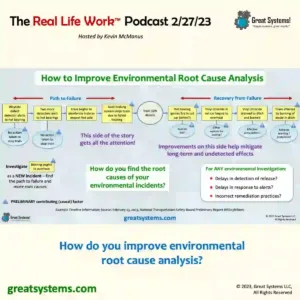

In order to improve ANY process, you must find and minimize the root causes of process waste. Most organizations would say that they know this. They could easily show you how they invest lots of time and money over time in attempts to do this.

However, what they might struggle to do is demonstrate to you the effectiveness of their current root cause analysis process. How do you find root causes? How effective are the root cause analysis questions your problem solvers ask?

Does your root cause analysis process contribute to corrective action failure?

Too many organizations rely on weak fixes that fail. Examples include reminders, discipline, and retraining. What is the case in your company? Why does this happen? Often, this is a result of the root cause analysis approach we use to find root causes.

The design of traditional approaches such as the 5 Why technique or fishbone analysis allow us to view human error and equipment failures as root causes. My experiences teach me that this is a bad thing to do. It is an analysis process error to blame problems on people and equipment.

The better option is to use a root cause analysis approach that looks for the systemic reasons a person makes mistakes.

Additionally, most process problems have a path to failure, even though we may fail to hunt for it. In other words, multiple errors and failures across the process or value stream build on each other. Some call this the path of causation.

An effective root cause analysis process looks at all the errors and failures that could help prevent a problem or make it less severe.

Keep improving!

Kevin McManus, Chief Excellence Officer, Great Systems

WATCH over 50 kaizen and workplace health improvement videos on my Great Systems YouTube channel.

CHECK OUT my ‘Teach Your Teams’ workbooks on Amazon.com

LIKE Great Systems on Facebook

© Copyright 2024, Great Systems LLC, All Rights Reserved