Operational Excellence Barriers

Ten Key Operational Excellence Barriers

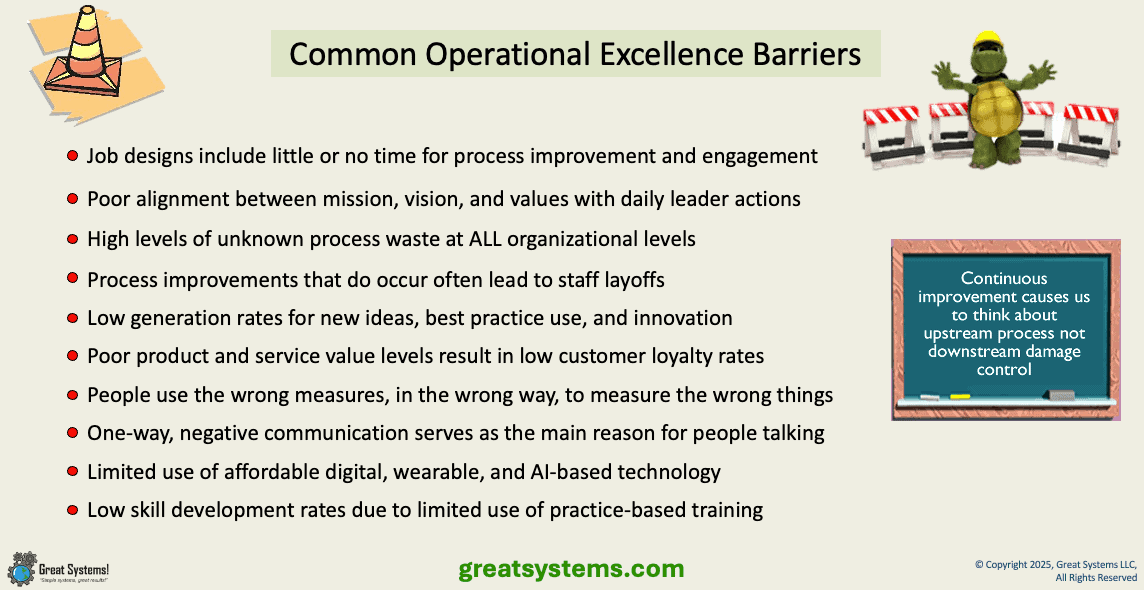

Poor work system design is the primary cause of our failure to sustain high levels of performance. My work with organizations reveals ten key operational excellence barriers. To move closer towards operational excellence, leaders must close these work system gaps.

Common barriers include poorly designed leader standard work systems, technology utilization systems, and measurement systems. What might your operational excellence barriers be?

Work systems give you what you design them to give you. Your personal food selection process determines to some degree the performance of your body. Similarly, the route you drive to work at a certain time of day affects how long it takes to make the trip. How do your daily habits (processes) affect your use of time?

Think about the compensation system you use at work. How does the 'package' of wages, benefits, and work environment you provide help engage all staff? How does that 'package' affect the levels of motivation, ownership, and commitment your people feel towards your organization?

Commonly, operational excellence barriers exist in organizations when work system designs fail to encourage and support high performance work.

Common barriers include poorly designed leader standard work systems, technology utilization systems, and measurement systems. What might your operational excellence barriers be?

Work systems give you what you design them to give you. Your personal food selection process determines to some degree the performance of your body. Similarly, the route you drive to work at a certain time of day affects how long it takes to make the trip. How do your daily habits (processes) affect your use of time?

Think about the compensation system you use at work. How does the 'package' of wages, benefits, and work environment you provide help engage all staff? How does that 'package' affect the levels of motivation, ownership, and commitment your people feel towards your organization?

Commonly, operational excellence barriers exist in organizations when work system designs fail to encourage and support high performance work.

How Does One Optimize Work System Performance?

This is not an 'either - or' argument. Work systems design and integration both constrains and aides organizational performance. The positive performance of one system offsets the negative impact of a different system.

For example, a strong leader standard work system can overcome some of the negatives that result from a poor compensation package design. The goal, of course, is to optimize work system performance.

Think of poor work systems design as being like a dog on a leash in the back yard. The length of the leash is the constraint to the dog's ability to explore and defend the yard. We can view the leash as a operational excellence barrier or performance restrictor plate. If we optimize the length of the leash, we provide benefits to both the dog and the owner. If we find and remove other performance restrictors, we gain further benefits.

As your key work systems improve in their design, site, business unit, and organizational performance improve. However, certain work systems contribute more than others.

For example, the ability to drive total team engagement and proactive process improvement is key. Similarly, your safety, risk, and security management work systems must work together effectively.

The key is that you must change work system design to get better results. Let’s explore these barriers to process improvement. Plus, we can explore the types of changes we must make to overcome them.

For example, a strong leader standard work system can overcome some of the negatives that result from a poor compensation package design. The goal, of course, is to optimize work system performance.

Think of poor work systems design as being like a dog on a leash in the back yard. The length of the leash is the constraint to the dog's ability to explore and defend the yard. We can view the leash as a operational excellence barrier or performance restrictor plate. If we optimize the length of the leash, we provide benefits to both the dog and the owner. If we find and remove other performance restrictors, we gain further benefits.

As your key work systems improve in their design, site, business unit, and organizational performance improve. However, certain work systems contribute more than others.

For example, the ability to drive total team engagement and proactive process improvement is key. Similarly, your safety, risk, and security management work systems must work together effectively.

The key is that you must change work system design to get better results. Let’s explore these barriers to process improvement. Plus, we can explore the types of changes we must make to overcome them.

Most performance improvement efforts fail to be sustained over time because management simply provides new tools and some training on the usage of those tools. They fail to change or install the systems that are needed to effectively support and encourage the use of these new tools and training over time.

WATCH over 50 kaizen and workplace health improvement videos on my Great Systems YouTube channel.

WATCH over 50 kaizen and workplace health improvement videos on my Great Systems YouTube channel.

OPEX Barrier #1: Job designs include little process improvement time

Many people don’t have time built into their jobs for projects. People often expect certain levels of performance to be reached, even though the existing processes are not capable of performing consistently at those levels.

Time is the fuel for high performance because it is required to improve process capability. There is a direct correlation between available project time in your jobs and your improvement rate. Where does this time come from?

For starters, consider using process improvement tools to minimize the substantial waste that exists in your meeting and e-mail / text processes. In most organizations, no one measures these processes, even though they often require 50% of a leader’s time each day.

What do you do to reduce meeting defects and optimize meeting cycle time? What actions do you take to reduce non-value added e-mails and texts?

Time is the fuel for high performance because it is required to improve process capability. There is a direct correlation between available project time in your jobs and your improvement rate. Where does this time come from?

For starters, consider using process improvement tools to minimize the substantial waste that exists in your meeting and e-mail / text processes. In most organizations, no one measures these processes, even though they often require 50% of a leader’s time each day.

What do you do to reduce meeting defects and optimize meeting cycle time? What actions do you take to reduce non-value added e-mails and texts?

OPEX Barrier #2: Poor MVV alignment with daily leader behaviors

In many companies, leaders behave as they wish, at least up to a point. For example, most leaders don’t communicate enough with their people. When they do, that communication is often negative.

Worse yet, they may act in ways that are inconsistent with the mission, vision, and values of the organization. Many leaders are not very good coaches, and their positive recognition and rule enforcement skills are often weak, if not non-existent.

How do we improve leadership behaviors on the job? For starters, consider using a portion of your annual climate survey to gauge leadership behavior consistency.

FedEx has done this for over twenty years via their Survey-Feedback-Action process. Most Malcolm Baldrige Performance Excellence award recipients doing something similar. The Gallup Q12 engagement survey mirrors the eleven statements in this index as well.

Worse yet, they may act in ways that are inconsistent with the mission, vision, and values of the organization. Many leaders are not very good coaches, and their positive recognition and rule enforcement skills are often weak, if not non-existent.

How do we improve leadership behaviors on the job? For starters, consider using a portion of your annual climate survey to gauge leadership behavior consistency.

FedEx has done this for over twenty years via their Survey-Feedback-Action process. Most Malcolm Baldrige Performance Excellence award recipients doing something similar. The Gallup Q12 engagement survey mirrors the eleven statements in this index as well.

OPEX Barrier #3: High levels of unknown process waste

Most improvement efforts focus on process improvement in the value stream. Processes that support, and often drive, that value stream, such as sales, marketing, human resources, and accounting, often lack improvement expectations.

How often do you see your accounting team talk about the efforts they make to minimize the time required to close the books each month?

How do we engage every work team in daily, process-focused improvement? For starters, you need structure. Design each job to include the necessary amount of project time.

Job descriptions for all staff must include process-based measures and quantitative improvement expectations. Most importantly, build such expectations into the job descriptions and compensation plans of leaders at ALL levels.

How often do you see your accounting team talk about the efforts they make to minimize the time required to close the books each month?

How do we engage every work team in daily, process-focused improvement? For starters, you need structure. Design each job to include the necessary amount of project time.

Job descriptions for all staff must include process-based measures and quantitative improvement expectations. Most importantly, build such expectations into the job descriptions and compensation plans of leaders at ALL levels.

OPEX Barrier #4: Process improvements result in staff layoffs

Instead of being recognized in a positive manner for their improvement successes, people often see the jobs of their friends, or even their own jobs, being eliminated. On more than one occasion, I have seen people purposely, but not admittedly, slow down or even fight against efforts to improve to help avoid personal or peer job loss.

How do we save money if we can’t reduce headcount? This is the wrong question to ask. Instead, we should ask how we can grow the business through sales, marketing, and other customer satisfaction-based process refinements. How can we make better use of the people we have on staff?

We don’t have to replace people one-for-one as they retire or otherwise leave, but layoffs are the ‘kiss of death’ to an improvement effort. The real lean upside comes when we improve our processes so that they provide consistent and high value to every customer.

How do we save money if we can’t reduce headcount? This is the wrong question to ask. Instead, we should ask how we can grow the business through sales, marketing, and other customer satisfaction-based process refinements. How can we make better use of the people we have on staff?

We don’t have to replace people one-for-one as they retire or otherwise leave, but layoffs are the ‘kiss of death’ to an improvement effort. The real lean upside comes when we improve our processes so that they provide consistent and high value to every customer.

OPEX Barrier #5: Low idea and innovation generation rates

As we learned with the last barrier, laying people off as a reward for improving their processes is not an effective strategy. Enhanced job security is one real benefit of a process improvement effort, but many people want more than that. How should we recognize improvement success?

When it comes to recognizing employee improvement efforts, there are a lot of options to consider. Certificates, mugs, and other giveaways lose their motivational impact over time. Spot rewards and employee of the month recognition often discount the efforts of others who helped make the improvement happen.

Provide a financial stake in the success of the business via profit sharing. Also, consider possible stock ownership as a best practice to adopt. Many leaders are hesitant, however, to make such bold moves.

When it comes to recognizing employee improvement efforts, there are a lot of options to consider. Certificates, mugs, and other giveaways lose their motivational impact over time. Spot rewards and employee of the month recognition often discount the efforts of others who helped make the improvement happen.

Provide a financial stake in the success of the business via profit sharing. Also, consider possible stock ownership as a best practice to adopt. Many leaders are hesitant, however, to make such bold moves.

OPEX Barrier #6: Low product or service value

This barrier is a close relative of the error we often make when we set performance goals. Remember, a work system gives you what it is designed to give you.

Another way to say this is that you can only go so fast. Don’t make the mistake of expecting too much change in the short-term. Consistent, daily process measurement is a 'must' to understand any process.

Apply statistical process control techniques, such as a moving range control chart, to measure and analyze process performance over time. Discover what each work process you own is currently capable of outcome-wise.

Plus, this tool tells you the probability of achieving a given performance level. To go outside the lines and improve to a significant degree often requires creativity and innovative ideas, not just process tweaks.

Another way to say this is that you can only go so fast. Don’t make the mistake of expecting too much change in the short-term. Consistent, daily process measurement is a 'must' to understand any process.

Apply statistical process control techniques, such as a moving range control chart, to measure and analyze process performance over time. Discover what each work process you own is currently capable of outcome-wise.

Plus, this tool tells you the probability of achieving a given performance level. To go outside the lines and improve to a significant degree often requires creativity and innovative ideas, not just process tweaks.

LISTEN NOW to my 'How to Change Work Culture' Real Life Work podcast.

OPEX Barrier #7: One-way, negative communication dominates

All organizations have resource limitations in the form of time and money constraints. Strategic priorities exist as well. People don't understand why their ideas are not selected for implementation when leaders fail to teach their teams about resource constraints. They wonder why certain improvement options are placed on hold or dropped, versus put in place.

One of the key first steps to improve the business literacy level in any organization is to get the information out there. The best way to fix this problem is to have senior leadership create and follow a formal communication plan.

Such a plan defines the key communication vehicles leaders use in the organization to communicate with the workforce. Plus, this plan identifies frequency of use, the affected groups, and the type of information communicated for each communication vehicle in use.

One of the key first steps to improve the business literacy level in any organization is to get the information out there. The best way to fix this problem is to have senior leadership create and follow a formal communication plan.

Such a plan defines the key communication vehicles leaders use in the organization to communicate with the workforce. Plus, this plan identifies frequency of use, the affected groups, and the type of information communicated for each communication vehicle in use.

OPEX Barrier #8: Limited use of digital, AI, and wearable technology

How often do you see people still move paper around as they process products and provide services? How many of your leaders spend time on document review for accuracy and completeness prior to approval? Are there times where they either delay the process and / or fail to catch key errors or omissions?

Today, low-cost technology exists to replace most routine tasks, be they cognitive or non-cognitive in nature. Why are we stuck in the past?

A lot of our problems is explained simply by the unprecedented rate of technology change - Moore's Law - in memory capacity and processing speed. Also, our schedules keep us from going out and looking at what others are doing from a best practice standpoint.

The digital transformation has begun, whether we recognize it or are affected by it ... yet.

Today, low-cost technology exists to replace most routine tasks, be they cognitive or non-cognitive in nature. Why are we stuck in the past?

A lot of our problems is explained simply by the unprecedented rate of technology change - Moore's Law - in memory capacity and processing speed. Also, our schedules keep us from going out and looking at what others are doing from a best practice standpoint.

The digital transformation has begun, whether we recognize it or are affected by it ... yet.

OPEX Barrier #9: People use the wrong measures the wrong way

Too many organizations fail to measure a significant percentage of their work processes at the process level? Instead, leaders use aggregate, and often static, metrics to review site, business unit, and organizational performance.

Most leaders can spot big problems at the 10,000-meter level. However, they need more sensitive, process-based measures to find and fix costly recurring challenges.

How do your people spend their time each day to support your different product and service value streams? How much of this daily work time is spent on non-value added activities?

Do you expect all leaders to capture, analyze, and improve the key measures for the processes they own? If you do, you can dramatically accelerate your improvement rate. Provide time in your Leader Standard Work plans to help drive process-based improvement across all work process types.

Most leaders can spot big problems at the 10,000-meter level. However, they need more sensitive, process-based measures to find and fix costly recurring challenges.

How do your people spend their time each day to support your different product and service value streams? How much of this daily work time is spent on non-value added activities?

Do you expect all leaders to capture, analyze, and improve the key measures for the processes they own? If you do, you can dramatically accelerate your improvement rate. Provide time in your Leader Standard Work plans to help drive process-based improvement across all work process types.

OPEX Barrier #10: Skill development failures from low practice training

Little time exists for formal classroom training in our next generation workplace. Few leaders have developed their ability to coach and teach in real-time. Remote learning can, and does, work. Unfortunately, most people have yet to master the requisite content design and delivery shifts.

The leverage point lies with local leaders who can teach the basics of effective process execution to a diverse team, on a real-time, on-demand basis. The use of low-cost video and audio can provide all team members with on-demand content to drive personal development. However, too many of us are still trapped in our vintage training design and delivery systems.

The leverage point lies with local leaders who can teach the basics of effective process execution to a diverse team, on a real-time, on-demand basis. The use of low-cost video and audio can provide all team members with on-demand content to drive personal development. However, too many of us are still trapped in our vintage training design and delivery systems.