What process improvement strategies do you have in your kaizen toolbox?

Process Improvement Strategies

You can use the process improvement strategies on this page to reduce waste, injuries, errors, equipment failures, and engagement challenges. Fortunately, I have been able to test them all out over the years.

In fact, I have never worked for a company that did not have some form of formal process improvement system in place. I have been able to experience additional process improvement strategies during my 20+ years of service as an Examiner for the national Baldrige Performance Excellence Award

If you have questions about any of these prices improvement strategies, please contact me. I think you can benefit from learning about, and experimenting with, all of them. I know that I learn something each time I use one of them.

Process Improvement Strategy Portal

You can use these links to jump to the strategy focus area you would like to explore further:

A Brief History of Process Improvement

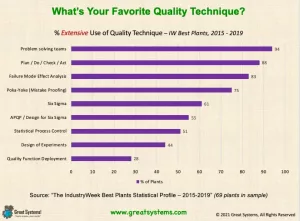

In general, a push for better process quality began with Shewhart back in the 1920s. W. Edwards Deming picked up on his statistical process control work and taught it to the Japanese following World War II. At that time, few executives would listen to him in the United States, The success of the Toyota Production System (real lean process improvement) in Japan inspired the Total Quality Movement in the United States in the early 1980s.

TQM transitioned into re-engineering to lead off the 1990s. Six sigma process improvement systems were both in use and being refined by General Electric, Allied Signal, and Motorola. Prior to 2002 or so, six sigma process improvement certifications had yet to become mainstream. Mikel Harry, among others, helped change all of that.

Six Sigma Goes Public

At the start of the 21st century, consultants from the successful six sigma companies began to develop and sell ‘public’ six sigma certifications. Jack Welch at General Electric further fueled the use of ‘six sigma’ as an improvement strategy and process. At the same time, lean process improvement strategies were emerging as options for use.

By 2010, use of the two process improvement strategies had morphed into lean six sigma, in most cases. I keep them separate here simply because one (six sigma) is really a measure of process quality. The other is a set of process improvement strategies.

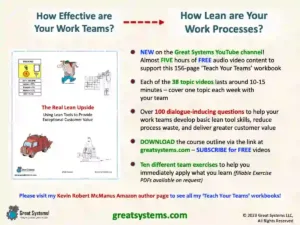

Raised on Employee Involvement and Work Teams

Work teams are at the heart of what we do here at Great Systems. I was raised on employee involvement, you might say. It was becoming a popular business improvement strategy when I entered the work world in 1981. During the next 15 years, participative management came to flourish in multiple forms, such as quality circles and self-directed work teams. Many organizations taught work team facilitation skills to their leaders, and group dynamics skills to all staff, in the 1990s.

I learned tons during this time, and I was able to set up and experiment with different team infrastructures. I was also fortunate to serve as a national leader for the Association for Quality and Participation during much of this time. This involvement connected me even more closely with best practice team-based process improvement strategies. All organizations need effective work teams to drive process excellence, improve through innovative projects, and support highly engaged, collaborative strategic support.

Team-Based Process Improvement Strategies

‘How to Increase Work Team Engagement’ Real Life Work podcast When I first entered the world of work more than 40 years ago, employee involvement was the rage. Now, organizations realize that both effective individual and work team engagement are critical to achieve true, sustainable operational excellence levels. Unfortunately, many don’t know how to increase work team engagement. Here are some engagement ideas that work for me.

What is a Work Team? What work team characteristics do the different types of process, project, and focus work teams possess in a high-performance workplace? Multiple work team characteristics help define these three common types of teams. This page summarizes the most common characteristics one might find.

How to Measure and Improve Employee Ownership People often ask me how to measure employee ownership in a company. Why is it important to have high levels of employee ownership? Without ownership, people have little to do more than show up and do what they are told. With ownership, people do more than do their job ‘right’ each day. They also serve as advocates for the organization’s products and services.

Do You Know How to Reduce Meeting Waste? Do your leaders know how to reduce meeting waste? Most say that too many meetings occur in the workplace each day. Plus, I think that a large percentage of these meetings are much less effective than they could be. My customers consistently feel the same way. This post’s content helps you solve that problem.

My Lean Six Sigma Process Improvement History

I will never forget sitting at the table at an Association for Quality and Participation leadership meeting 20 years ago. The discussion centered around a rumor that private six sigma certifications were about to go public. Consultants from within the Six Sigma Big Three – Allied Signal, Motorola, and General Electric – were going to share their proven certification formulas. We had to decide if we should jump on the bandwagon. We didn’t, but that did not stop the 21st century Six Sigma wave in the process improvement world.

Before then, six sigma was a measure of quality. I knew about the concept from my studies of Bob Galvin’s work at Motorola. Six sigma became more than a measure a variation after that. It became ‘3.4 defects per million opportunities.’ The six sigma process improvement strategy worked at the Big Three because it included a very supportive infrastructure. This was something few quality circles had previously. Plus, their approach required teams to use a structured project selection approach. This is not how most practice six sigma today. However, that is where the roots of today’s programs lie.

I was a lean thinker before I learned about the Toyota Production System. However, my studies of the work of Toyoda, Shingo, Ishikawa, and Ohno only further stoked the process improvement fire ignited by my industrial engineering degree. Industrial engineering, sound ergonomics, and human engineering are all a part of the lean six sigma process improvement strategy set. Plus, there are other great tools in the tool box.

Lean Six Sigma Process Improvement Strategies

How to Apply 5S Lean Tools Organizations can gain many benefits when they install a 5S process. This page explores how to apply 5S lean tools in a simple, proven, and results-driven way to drive kaizen and operational excellence.

Frequently Asked Equipment Reliability / TPM Questions My hope is that the top seven equipment reliability improvement tips I share in this post help your work teams save time and money, reduce failures, and optimize asset health.

How to Write Effective Corrective Actions All too often, we attempt to use weak fixes to prevent future problems of a significant nature. How effective are your actions?

More Process Improvement Strategies

You can find additional pages on this site with a process improvement focus.

Measuring Process Improvement Effectiveness Measuring process improvement effectiveness is a challenge to many. This post explores how the best organizations track ideas, best practices, and innovations to help overcome this challenge.

Workplace Safety Best Practices The work system changes one needs to make in order to shift from a reactive safety focus to a proactive safety focus are clear. I have found some great workplace safety best practices on this page.

How to Measure and Improve Your Process Improvement Work System Unfortunately, the waste in our ‘higher level’ processes might be much more costly than those processes we use to create products or provide services on a daily basis. How do you measure and improve your process improvement work system?

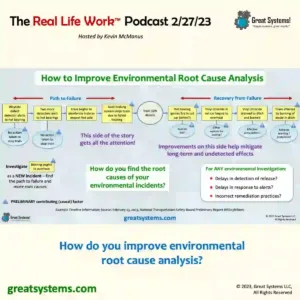

Root Cause Analysis Strategies

As with other process improvement tools, root cause analysis has changed over the past fifty or so years. It all began with the 5 Why’s and fishbone, or Ishikawa, diagrams. Today, specialized root cause analysis approaches like TapRooT® and other exist.

How Do You Find Root Causes? This page looks at the similarities and differences between five common techniques organizations use for root cause analysis – the 5 Whys, Kepner-Tregoe Problem Analysis, fishbone or Ishikawa diagrams, change analysis, fault tree analysis – and the TapRooT® root cause analysis process.

Five Bad Root Cause Analysis Questions How effective are your root cause analysis questions? As a Western culture, we don’t do very well when it comes to root cause analysis. All too often, we blame people, equipment, or the weather. In this post, I include some very good root cause analysis questions you should ask.

‘Root Cause Frequently Asked Questions’ Real Life Work podcast For almost 20 years, I have taught the TapRooT® root cause analysis process. In this post, I share some of the questions people most often on the ‘effective root cause analysis’ topic.

Evaluating Root Cause Analysis Processes In order to improve ANY process, you must find and minimize the root causes of process waste. Many organizations can easily show you how they invest lots of time and money over time on formal root cause analysis. However, they often struggle to demonstrate current root cause analysis process effectiveness.

Keep improving!

Kevin McManus, Chief Excellence Officer, Great Systems

WATCH over 50 kaizen and workplace health improvement videos on my Great Systems YouTube channel.

CHECK OUT my ‘Teach Your Teams’ workbooks on Amazon.com

LIKE Great Systems on Facebook

© Copyright 2024, Great Systems LLC, All Rights Reserved