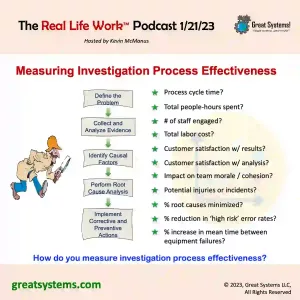

Given the resource investment made, it is key that leaders measure and improve investigation process effectiveness.

How to Measure Investigation Process Effectiveness

Recently, I received a great e-mail question from one of my TapRooT® root cause analysis course participants. His question was basic, but meaningful. “What are your thoughts on how to measure investigation process effectiveness?” he asked.

He went on to explain that he wanted my insights partially because he knew I was a measurement freak. More importantly, he felt pressure by his boss to focus on investigation timeliness over everything else. This post represent my best efforts to answer his questions. If you have others, feel free to ask.

Buy my new ‘How to Lead Great Investigations’ book on amazon.com

How do You Measure Investigation Process Effectiveness?

Investigating problems, like most work activities, is a process. Have you read my Vital Signs measurement book, sat in on one of my measurement workshops, or simply done a lot of process measurement yourself?

If so, you know that processes produce a variety of results with each cycle, and not just one or two. At a minimum, all processes have vital signs that relate to time, cost, quality, morale / teamwork, and safety dimensions.

All too often however, we place too much focus on the time measure. In doing so, we often compromise other results like quality, morale / teamwork, and safety. For example, I frequently see people do poor root cause analysis and write weak corrective actions in order to complete their problem solving work on time.

Is investigation timeliness the primary measure you focus on? If so, you might not find the true root causes of your problems. Worse yet, you might fail to notice that your fixes fail all too often.

Ironically, timeliness is a quality measure. We want to meet one of our customer’s key requirements. Unfortunately, we often compromise our ability to meet other requirements when we focus too much on time.

EXPLORE MORE: Measuring and Evaluating Workplace Safeguard Effectiveness

Key Measures of Investigation Process Effectiveness

There are many different ways to measure investigation process effectiveness. However, I will just focus on the basics here. If you want to talk about this topic in more detail, feel free to connect with me. Then, we can dig into your particular challenges in more detail. With no further ado, here are some key investigation process measures most people should track, but often don’t track.

DISCOVER MORE: Workplace Safety Best Practices

How Much Investigation Process Time Do You Invest?

I like to track two time dimensions when I look at investigation process performance. First of all, what is our average investigation process cycle time in days? This often the measure leaders focus on the most. How long did it take to complete the investigation?

Second, how many people hours did we invest to achieve this ‘number of days’ cycle time? Sadly, few problem solving teams track this basic measure. In turn, it is even more difficult to optimize future investigation process cycle times.

We often make a mistake when we use groups that are too large to try to solve problems. However, you can involve many people in evidence collection. Unfortunately, we lose process efficiency and effectiveness when we try to put them all in the same room at the same time. Additionally, we often lack good group facilitators or fail to collect good evidence. This only magnifies the potential for lost time and money when a group meets.

LEARN MORE: Does Your Team Structure Drive Operational Excellence?

What is the Cost of Your Investigation Process?

I firmly believe that if managers knew the real costs of their process challenges, they would make very different decisions. Do you track the costs of your investigation process? At a minimum, we should know the costs of the people hours we invest as we try to solve a problem. Ideally, we should also include at least some of the cost of process errors (waste) in our cost totals as well.

You don’t have to have an exact number here. For example, you can multiply a weighted average wage rate by the total people hours you invest to give you a good reference. However, cost is not a value to always minimize! Instead, we should try to optimize the hours and dollars we invest trying to solve a problem.

To do this, look for correlations between our time and cost measures and other key investigation process measures over time. Value is the goal. What quality of fixes do we get for the time we invest?

Investigation Process Safety

This should be one of the easier measures to obtain. If you have an injury as a result of the investigation process itself, shame on you. This can, and does, happen however. Additionally, one could argue that we should capture similar past injuries as part of the investigation.

At a minimum, we should track whether or not we experience ANY type of injury, no matter how minor, as a result of our investigative efforts. We should keep in mind that if we fail to secure a scene, release a scene too quickly, or continue to work when hazards exist, we will raise the potential for this to happen.

EXPLORE MORE: How to Measure and Improve Your Process Improvement Work System

Investigation Process Morale and Teamwork

How often do we damage our company culture when leaders investigate problems in an accusatory manner? How often do we blame people instead of systems and damage our leadership credibility?

A ‘blame’ work culture makes it difficult to obtain good data and evidence. Such a culture makes it even more difficult to put effective fixes in place.

Morale and teamwork are not that hard to measure. Unfortunately, we often fail to even give these factors consideration when we look at investigation process effectiveness. A problem solving team might work very hard to collect a well-rounded set of evidence, only to get the business when they take too long to do so.

Surveys serve as the primary tool for measuring an investigation process from a morale and teamwork perspective. For example, you can use a post-investigation survey to gauge team and customer satisfaction with the investigation process itself. These surveys do not have to be long – 4-5 questions are typically adequate.

Plus, you can include a couple of questions with an investigation process involvement and effectiveness focus in your regular workforce climate survey. When you combine these big picture results with investigation-specific results, you get a better picture of true process outcomes.

LISTEN to my ‘How to Measure Investigation Effectiveness’ Real Life Work podcast

Investigation Process Quality

The key question to ask here is “What indicators serve as proof that our fixes worked?” Many people feel that if the incident or problem being investigated does not occur again, then the fixes were effective.

There is nothing wrong with the use of such an indicator. However, consider the use of more error-sensitive leading indicators on their investigation process effectiveness scorecard.

Behavior-based observation rates provide a better indication of fix effectiveness. Waiting for another bad thing to happen is not the best way to know if your fixes work or not.

Instead, we should search for trends that show reductions in the errors, safeguard gaps, and equipment failures that led to the incident. Similarly, we should measure if the root causes we found now occur less frequently.

Keep improving!

Kevin McManus, Chief Excellence Officer, Great Systems

WATCH over 50 kaizen and workplace health improvement videos on my Great Systems YouTube channel.

CHECK OUT my ‘Teach Your Teams’ workbooks on Amazon.com

LIKE Great Systems on Facebook

© Copyright 2024, Great Systems LLC, All Rights Reserved